Concrete is one of the most widely used construction materials due to its durability, strength, and adaptability for various structures. However, the quality of concrete depends heavily on its workability, consistency, and water-cement ratio. One of the most common methods to quickly measure the workability of fresh concrete is the slump test for concrete. This test provides an immediate indication of how fluid or stiff the concrete is, helping engineers, contractors, and site workers determine whether the mix is suitable for the intended construction application. Understanding the principles and procedure of a slump test for concrete is essential for ensuring both the quality and longevity of concrete structures.

Importance of Slump Test for Concrete

The slump test for concrete plays a crucial role in construction quality control. Workability affects not only the ease of placing concrete but also the strength and durability of the hardened material. If concrete is too stiff, it may be difficult to compact properly, leading to voids or honeycombing. If it is too fluid, it may segregate, leading to uneven consistency and reduced strength. By performing a slump test for concrete, engineers can detect deviations in mix proportions, water content, or aggregate distribution and take corrective measures immediately. This helps prevent structural failures and ensures that the concrete performs as intended in its final application.

Principles Behind Slump Test for Concrete

The slump test for concrete is based on a simple principle of measuring the vertical subsidence of freshly mixed concrete when removed from a conical mold. The test reflects the consistency of the mix and its ability to flow under its own weight. The standard procedure uses a slump cone, which is filled in three layers with tamping in between, and then lifted carefully. The difference in height between the mold and the settled concrete is recorded as the slump. This measurement indicates whether the concrete mix is stiff, plastic, or highly workable. Understanding these principles allows site personnel to evaluate mix quality in real time.

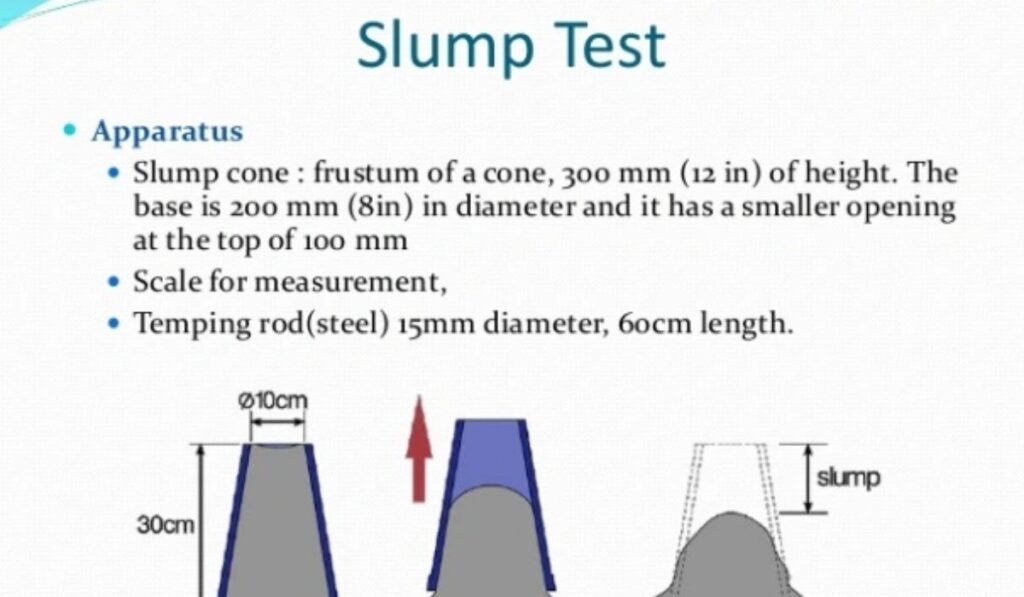

Equipment Required for Slump Test for Concrete

To perform a slump test for concrete accurately, certain tools and equipment are required. These include a standard slump cone made of metal or plastic, a base plate to support the cone, a tamping rod to compact the concrete, and a measuring scale or ruler to determine the slump value. Additionally, water and cleaning materials may be needed to prepare the equipment for repeated tests. The slump test for concrete is designed to be simple and portable, allowing quick assessment on construction sites without complex laboratory equipment. Proper use of the tools ensures accurate readings and reliable evaluation of concrete workability.

Step-by-Step Procedure of Slump Test for Concrete

Performing a slump test for concrete involves a standardized procedure to ensure accuracy and repeatability. First, the slump cone is placed on a firm, flat base. The cone is filled in three equal layers, with each layer being tamped thirty times using the tamping rod to compact the concrete. After the cone is fully filled, the top is leveled, and the cone is lifted vertically without disturbing the concrete. The resulting subsidence, or slump, is measured from the original top of the cone to the highest point of the concrete after settlement. This measured value is recorded and interpreted according to standard guidelines to assess whether the concrete mix is suitable for its intended purpose.

Types of Slump Observed in Slump Test for Concrete

During a slump test for concrete, three primary types of slumps may be observed: true slump, shear slump, and collapse slump. A true slump occurs when the concrete subsides evenly, indicating a uniform and workable mix. Shear slump happens when one part of the concrete shears off, which may indicate poor cohesion or excessive water content. Collapse slump occurs when the concrete collapses completely, signaling an overly wet or unstable mix. Recognizing these types helps engineers determine whether adjustments are needed in the concrete mixture before placement, ensuring optimal performance in the final structure.

Factors Affecting Slump Test for Concrete

Several factors influence the outcome of a slump test for concrete. Water content is the most significant, as higher water-cement ratios increase slump while lower ratios reduce it. Aggregate size, shape, and grading also affect workability, as angular or poorly graded aggregates may lead to stiffer mixes. Admixtures such as superplasticizers can increase slump without adding excess water. Environmental conditions, including temperature and humidity, also play a role in fresh concrete behavior. Understanding these factors is essential for interpreting slump test for concrete results accurately and making informed adjustments to achieve the desired workability.

Limitations of Slump Test for Concrete

While the slump test for concrete is valuable for assessing workability, it has limitations. It cannot directly measure strength, durability, or setting time of concrete. The test is more suitable for medium and low workability concrete; very stiff or very fluid mixes may not provide reliable readings. Variations in testing technique, such as improper tamping or uneven lifting of the cone, can also affect results. Despite these limitations, the slump test remains an essential field test because it offers quick, practical, and inexpensive feedback on mix consistency, allowing for real-time corrections before concrete placement.

Applications of Slump Test for Concrete

The slump test for concrete is widely used across various construction projects. It is particularly useful for assessing concrete used in foundations, slabs, beams, columns, and pavements. By determining the mix’s workability, the test ensures that concrete can be placed, compacted, and finished properly. Slump test results also help in quality control, allowing engineers to verify that the concrete delivered to the site matches the specified design mix. Furthermore, the test aids in adjusting water content or admixtures in response to environmental conditions, ensuring uniform performance across different batches of concrete.

Best Practices for Conducting Slump Test for Concrete

To achieve accurate and consistent results from a slump test for concrete, certain best practices should be followed. These include using standard equipment, following the step-by-step procedure precisely, performing the test on a flat and firm base, and recording readings immediately. Repeating the test for multiple samples from the same batch helps confirm consistency. Avoiding contamination from previous mixes and ensuring proper tamping are also critical. Adhering to these best practices ensures that the slump test for concrete provides reliable data for evaluating mix workability and making adjustments to maintain construction quality.

Conclusion

The slump test for concrete is a simple, reliable, and widely accepted method for evaluating the workability and consistency of fresh concrete. By providing immediate feedback, it helps engineers and construction professionals ensure that the concrete mix meets project requirements, can be placed efficiently, and will achieve desired strength and durability. Understanding the procedure, types of slump, factors affecting results, and limitations of the test is essential for successful concrete placement. Implementing this field test as part of quality control measures ensures that construction projects proceed smoothly and that the resulting structures are both safe and long-lasting.

Frequently Asked Questions

1. What is a slump test for concrete?

- A test to measure the workability and consistency of fresh concrete using a slump cone.

2. Why is a slump test for concrete important?

- It ensures proper workability for easy placement and uniform compaction of concrete.

3. What types of slumps can be observed?

- True slump, shear slump, and collapse slump indicate different mix conditions.

4. What factors affect the slump test for concrete?

- Water content, aggregate type, admixtures, and environmental conditions affect results.

5. Can a slump test measure concrete strength?

- No, it only assesses workability and consistency, not strength or durability.